Tokyo, Japan, October 18, 2013 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a China-produced tapered roller bearing for travel reduction gears used in construction machinery such as hydraulic excavators that has a higher level of reliability than the conventional bearing. This bearing was locally sourced and produced to make it possible to provide a steady supply of the cost-competitive, high-quality, short-lead-time bearings that are in demand in developing countries.

NSK is expanding the sales of this bearing in the construction machinery markets of developing countries and is targeting 2 billion yen in global annual sales in 2016.

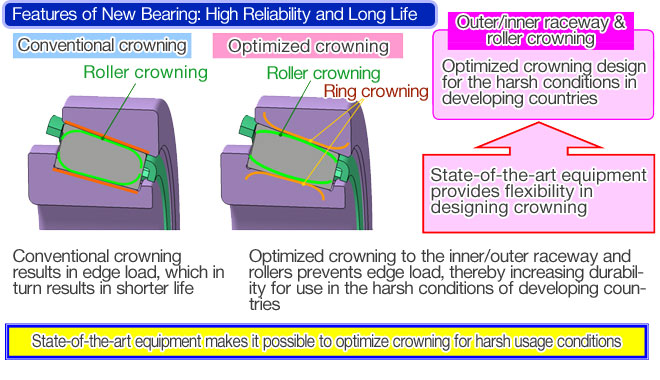

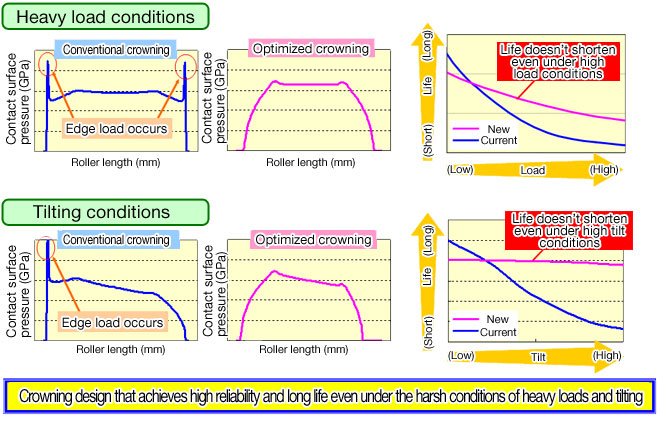

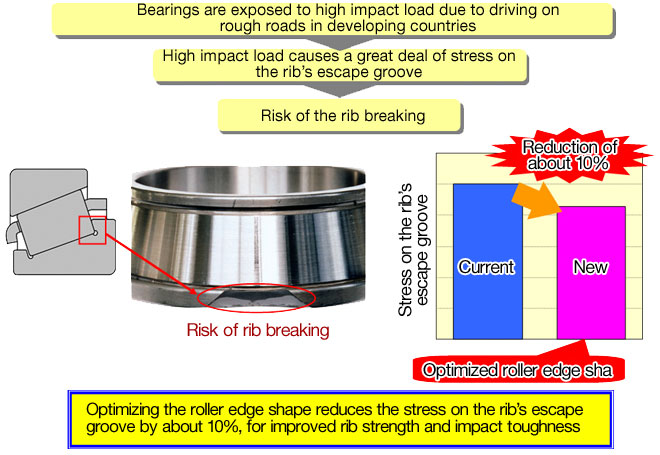

Tapered roller bearings used in the travel reduction gears of construction machinery such as hydraulic excavators are used in very harsh conditions that include heavy loads and high-impact loads. This is even more so the case in developing countries, where construction machinery is often used continuously for long hours and over long stretches of rough roads. Developing countries also pose unique challenges in terms of the poor precision of the parts surrounding the bearing as well as the lack of experience workers have in regard to handling bearings.

In response to this situation, NSK used locally sourced materials to design an optimum bearing specification for the unique conditions in developing countries. In addition, NSK introduced state-of-the-art, high-precision machining technology to the factory in China in order to achieve the local production of high-quality bearings at a cost-competitive level with shorter lead times.

This bearing not only provides the durability and reliability required by the harsh usage conditions in developing countries, but it also provides cost competiveness and shorter lead times through local production. NSK endeavors to leverage these benefits to expand sales of this bearing in developing countries.